Physical Address

304 North Cardinal St.

Dorchester Center, MA 02124

Physical Address

304 North Cardinal St.

Dorchester Center, MA 02124

Introduction

In the vast realm of printing technologies, one method stands out for its versatility, precision, and ability to decorate even the most complex surfaces – pad printing. This innovative technique has found its application in various industries, from electronics to medical devices, leaving an indelible mark on the products we encounter daily. In this comprehensive blog post, we will delve into the intricacies of pad printing, exploring its history, the mechanics behind the process, and its wide-ranging applications.

Pad printing, also known as tampon printing, originated in the mid-20th century in Switzerland. The technique was developed to address the challenges of printing on irregular, curved, or textured surfaces that traditional printing methods struggled to handle.

Since its inception, pad printing has undergone significant advancements, propelled by technological innovations and a growing demand for high-quality printing on diverse materials. The evolution of pad printing has transformed it from a niche process to a mainstream solution for various industries.

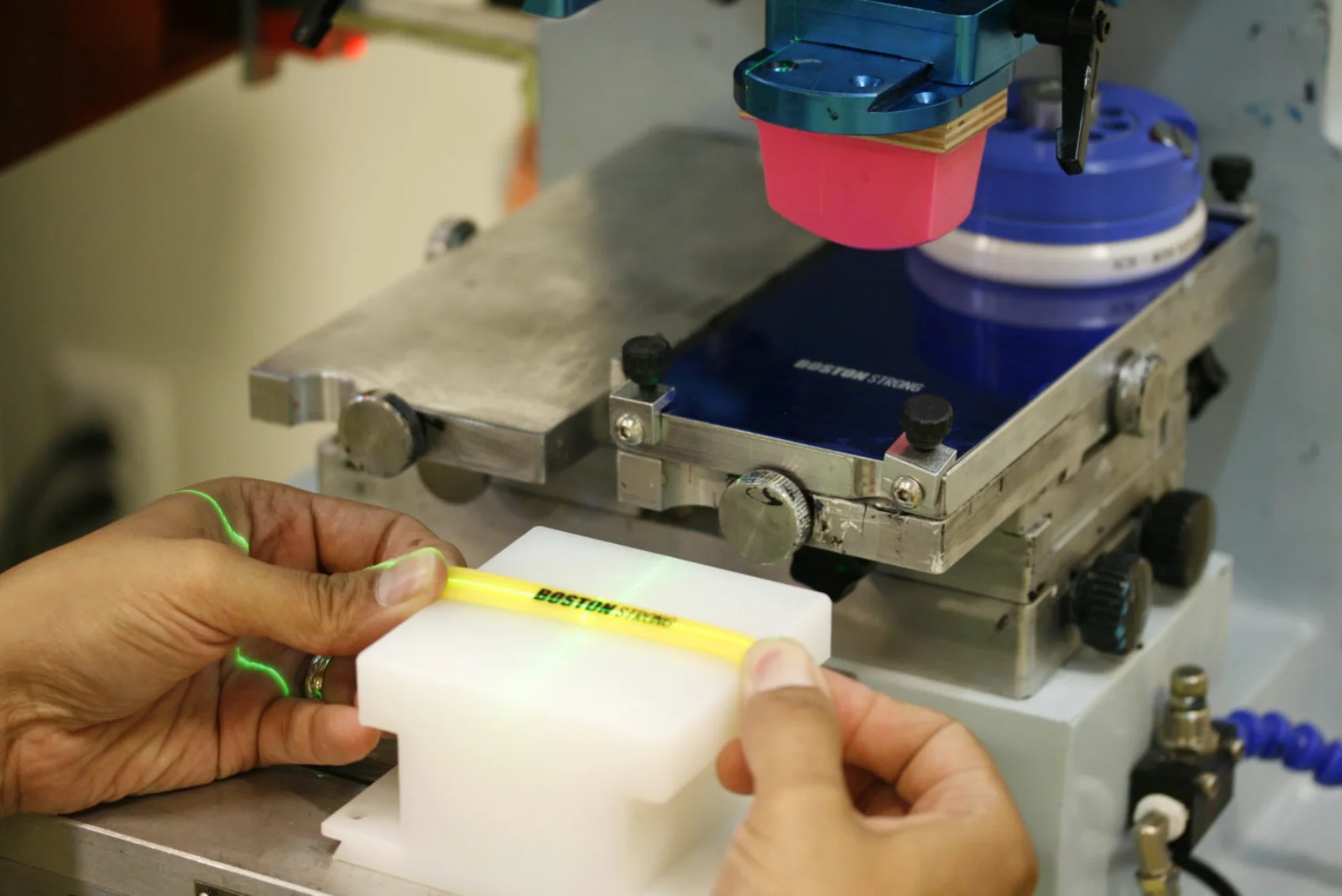

At the heart of the pad printing process lies the silicone pad, a flexible and deformable material that transfers the ink from the printing plate to the substrate. The pad’s composition and quality play a pivotal role in achieving precise and consistent prints.

The printing plate, often made of photopolymer, carries the image to be printed. Through a series of chemical processes, the desired design is etched onto the plate with remarkable detail and accuracy.

The ink cup houses the ink and features a doctor blade, which removes excess ink from the plate, leaving only the ink in the etched image. This controlled transfer ensures clean and sharp prints.

Pad printing has become a staple in the electronics industry for printing on circuit boards, buttons, and casings. The precision of the process ensures that even the tiniest components receive clear and durable markings.

In the medical field, where sterilization and durability are paramount, pad printing finds applications on instruments, implants, and medical packaging. The ability to print on curved and irregular surfaces makes it an ideal choice for medical equipment.

The automotive industry relies on pad printing for labeling and branding on various components, including dashboard buttons, switches, and logos. The resilience of pad-printed markings against environmental factors makes it a preferred choice.

From pens to keychains, pad printing is widely used for promotional products. The process allows for vibrant and lasting prints on a multitude of materials, enhancing the visual appeal of promotional items.

Advancements in digital technology have influenced pad printing, leading to the emergence of digital pad printing systems. These systems offer enhanced precision, quicker setup times, and the ability to reproduce intricate designs with unparalleled accuracy.

As environmental consciousness grows, manufacturers are exploring eco-friendly ink options for pad printing. Water-based and UV-curable inks are gaining popularity, reducing the environmental impact of the printing process.

Despite its versatility, pad printing faces challenges related to color matching, especially on dark or transparent substrates. Overcoming these challenges requires ongoing research and development in ink formulations and printing techniques.

The future of printing looks promising with ongoing innovations in materials, inks, and equipment. As industries continue to demand high-quality and customized prints, pad print is likely to evolve further, offering new possibilities and applications.

In conclusion, pad stands as a testament to the marriage of art and science in the world of printing technologies. Its ability to navigate the complexities of diverse surfaces and materials has solidified its place in industries where precision and durability are non-negotiable. As technology continues to advance, the future holds exciting possibilities for pad printing, promising even greater flexibility, environmental sustainability, and expanded applications across various sectors.