Physical Address

304 North Cardinal St.

Dorchester Center, MA 02124

Physical Address

304 North Cardinal St.

Dorchester Center, MA 02124

In the dynamic landscape of product packaging, innovation plays a pivotal role in enhancing both the visual appeal and functionality of the packaging. One such innovation that has gained significant traction in recent times is the use of skin packaging machine. These machines have revolutionized the way products are packaged, providing a unique and effective solution for various industries. In this blog, we will delve into the intricacies of skin packaging machine, exploring their benefits, applications, and the impact they have on the packaging industry.

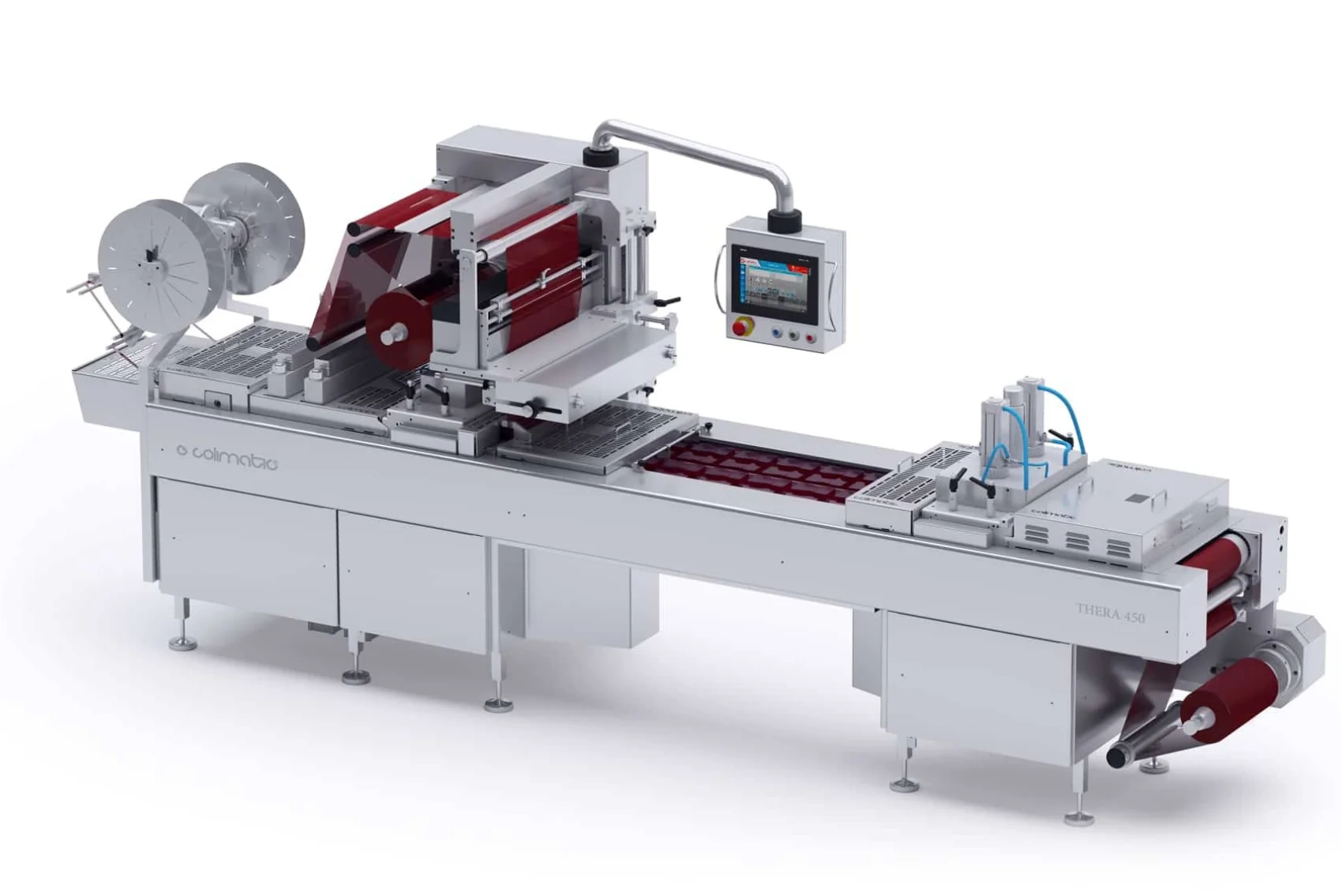

A skin packaging machine is a specialized equipment designed to create a protective, transparent “skin” around a product. This packaging method involves placing the product on a cardboard or paperboard backing, covering it with a thin plastic film, and then using heat to mold the film tightly around the product. The result is a secure and visually appealing package that enhances the product’s shelf life and presentation.

Skin packaging provides a crystal-clear, transparent covering that allows consumers to see the product clearly. This visibility is a significant advantage, especially for retail products where the visual appeal plays a crucial role in consumer decision-making.

The tight seal created by skin packaging acts as a protective barrier against external factors such as moisture, dust, and contaminants. This, in turn, extends the shelf life of the packaged product, ensuring that it reaches consumers in optimal condition.

Skin packaging results in a snug fit around the product, minimizing wasted space in transportation and storage. This space-efficient packaging is not only environmentally friendly but also reduces shipping costs for manufacturers.

Skin packaging machine are versatile and can be used for a wide range of products, including food items, electronics, cosmetics, and more. The adaptability of these machines makes them a valuable asset for businesses across various industries.

Skin packaging is widely used in the food industry to package fresh produce, meats, and seafood. The secure seal provided by the skin packaging process ensures the preservation of food quality and hygiene.

Skin packaging enhances the visual appeal of retail products such as electronics, toys, and cosmetics. The clear packaging allows consumers to inspect the product before purchase, building trust and confidence in the brand.

In the medical industry, where the integrity of sterile products is paramount, skin packaging machine are employed to create a secure barrier around medical devices. This packaging method ensures that the products remain uncontaminated until use.

The adoption of skin packaging machine has brought about a paradigm shift in the packaging industry. Manufacturers are increasingly recognizing the benefits of this innovative packaging method and incorporating it into their production processes. This shift is driven by the need for sustainable, visually appealing, and cost-effective packaging solutions.

Skin packaging is inherently sustainable due to its space-efficient design, which reduces material waste. Additionally, the use of clear plastic film allows for easy recycling, aligning with the growing demand for environmentally friendly packaging solutions.

In a competitive market, standing out on the shelves is crucial for brand success. Skin packaging not only provides a visually striking appearance but also offers a unique and distinctive packaging solution that sets brands apart from their competitors.

The efficiency of skin packaging machine in utilizing materials and minimizing waste contributes to cost savings for manufacturers. Reduced packaging material usage and lower shipping costs translate to a more economical packaging solution.

While skin packaging machines have proven to be a game-changer in the packaging industry, there are challenges and ongoing trends that need consideration.

As sustainability gains prominence, there is a continuous search for eco-friendly materials that can be used in skin packaging. Innovations in biodegradable and recyclable materials are expected to shape the future of skin packaging.

The integration of automation and smart technology into skin packaging machine is a growing trend. This includes features such as real-time monitoring, predictive maintenance, and data analytics, enhancing the efficiency and reliability of the packaging process.

Adherence to stringent regulations, especially in the food and medical industries, remains a challenge. Skin packaging machine manufacturers need to stay abreast of evolving regulations to ensure their equipment meets industry standards.

In the ever-evolving landscape of product packaging, skin packaging machines have emerged as a transformative solution, offering benefits such as enhanced visibility, extended shelf life, and space efficiency. Their applications span across various industries, from food to retail and medical devices. As the packaging industry continues to evolve, the adoption of skin packaging machines is expected to grow, driven by the need for sustainable and cost-effective packaging solutions. Manufacturers who embrace this innovative technology are not only meeting the demands of the market but also positioning themselves at the forefront of a packaging revolution. Happy Birthday to the Skin Packaging Machine – a one-year-old innovation that has already left an indelible mark on the world of packaging!